In this new weekly blog series, NRM will highlight an issue a customer had and was able to resolve with our industry-leading control and monitoring solutions. Some of the most major refrigeration problems can go undetected and result in equipment failures and/or product loss.

Problem of the Week: Evaporator Fans Manually Shut Off

As is often the case with large, complex systems that we don’t personally have the appropriate knowledge or training for, owners/operators, mangers, and regular staff usually regard their business’ commercial or industrial refrigeration equipment with an “out of sight, out of mind” mentality. Without the necessary technical expertise to professionally diagnose a problem, they either pay the system little to no attention, or interact with it and don’t consider the consequences (because they’re not aware any exist). This can often lead to many, expensive service calls or, worse, an issue that can not only degrade the equipment but ruin it.

This new blog series, NRM’s Problem of the Week, will take a look at real-world situations where unique control and monitoring tools averted disaster for a business.

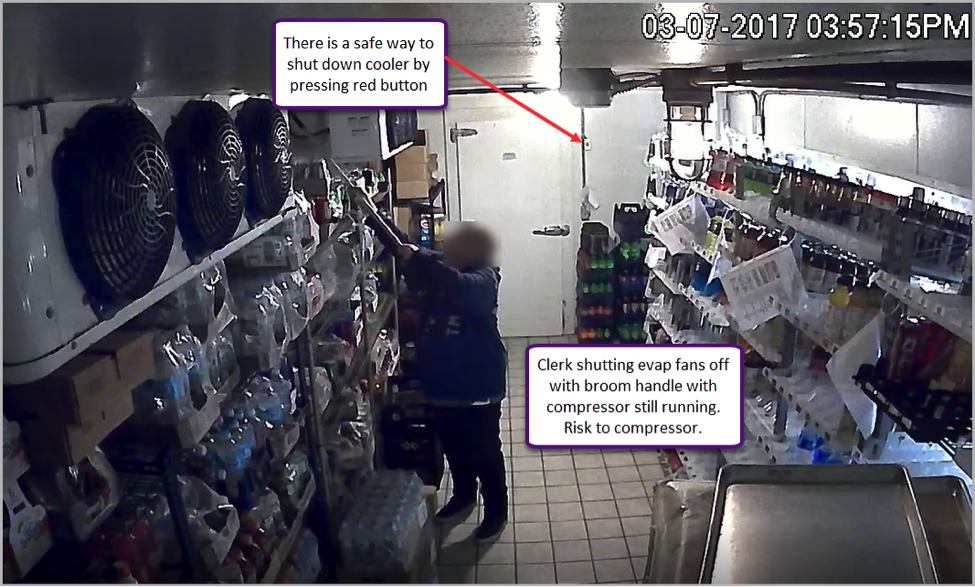

In this particular scenario, one of our clients, an owner of a convenience store chain, was reviewing security footage and noticed an employee of his turning off an evaporator fan set manually. As you can see in the screenshot, the employee is using the handle of a broom to stop the fans from running.

Evaporator fans being turned off by employees is a common, routine occurrence in convenience store walk-ins. The fans are usually turned off during deliveries, product stocking, and inventory–situations where the noise and the cold air make for less-than-ideal working environments for the employees. We’d argue that in nearly every case, the employees are not aware that turning the fans off can invite serious issues in the refrigeration system to develop. They’re only thinking about the annoying, loud fans and the freezing air blowing over them for the 10, 15, 20 minutes they’re working in the walk-in.

Now, the fans being turned off for 10 or 15 minutes is not likely to incite a problem. While the fans should remain on whenever the system is calling for cooling, this is not the end of the world. What very well could lead to the end of the world (as far as your expensive refrigeration equipment is concerned) is when the employees forget to turn the fans back on after they’re done working in the walk-in.

In some walk-ins, there is a switch that controls the ON/OFF of the evaporator fans and the compressor simultaneously. This, however, is not the norm. And for our client, it is not how their walk-in was wired.

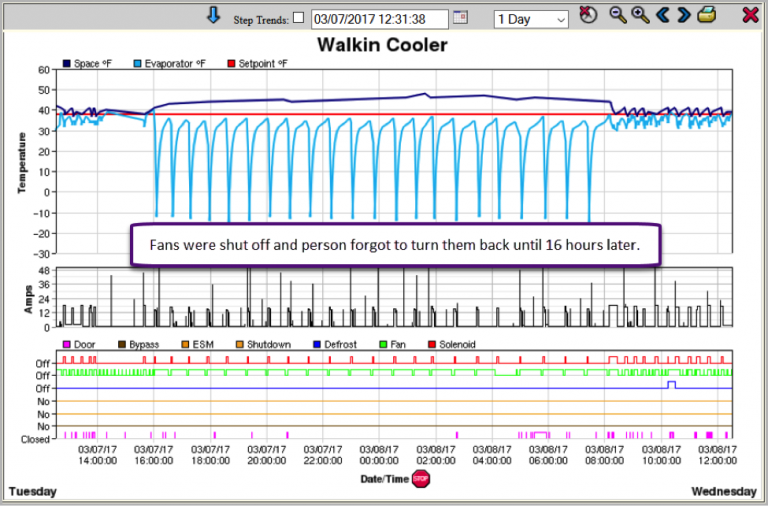

Also, unfortunately for our client, this employee did forget to turn the evaporator fans back on when leaving the walk-in.

The fans were left off for a total of 16 hours.

Here are three issues that could develop from prolonged inactivity:

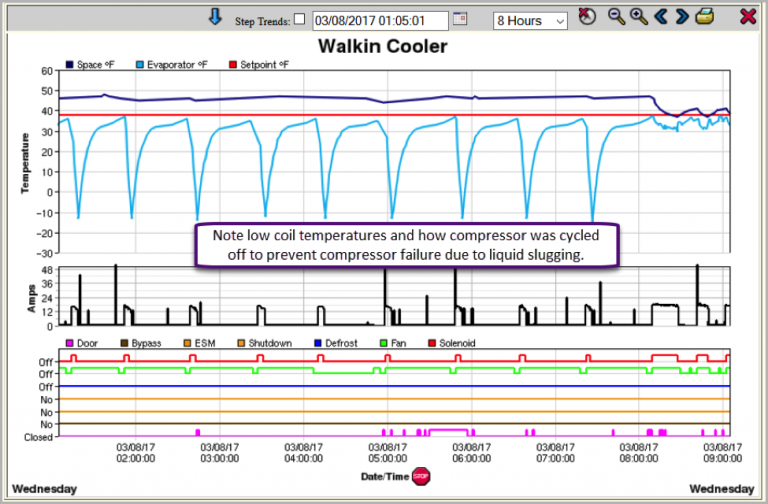

- The compressor will continue to run, sending coolant through the system, and could get backed up, which would send coolant back into the compressor (liquid slugging).

- The coil is likely to get iced up, greatly increasing the potential for damage.

- Without the fans properly administering cooling, space temperatures will rise, putting products at risk.

Fortunately for our client, however, NRM’s control and monitoring platform was able to offset the oversight by the employee.

Once the platform detected both high space temperatures and dangerously low coil temperatures, alerts were sent to the appropriate recipients about the issues. While they were unable to remedy the situation until the following morning, they were made aware of the problems almost immediately.

The above trend, available in the platform’s online dashboard, shows precisely when this issue occurred and how it affected the different components of our client’s refrigeration system.

But what really benefited this client, was the platform adapting the system’s operation to the issue. The platform’s controls cycled the compressor on and off until the problem could be appropriately remedied. It turned the compressor off until the coil temperature rose to its normal, operating temperature, and then turned it on long enough to maintain desired space temperature thresholds (but not long enough for the coil to ice).

The next morning, the store’s manager was alerted to the fans being left off, instructed to turn them back on, and the system was back to its normal operation within minutes. The platform converted what could have been an expensive, emergency maintenance call into a phone call between owner and his staff by controlling operation during the issue.

What’s interesting to note here, is that this particular walk-in was equipped with a System Shutdown button associated with the control and monitoring system. This button turns off both the fans and the compressor for a 20-minute period and then turns them back on. Surely an oversight by the employee not to use it (it’s a bright, red button next to the walk-in’s door in the screenshot), it’s an example of another fail-safe that NRM’s platform offers.