AARA

Members

Act now and take advantage of generous incentives that can help you get energy efficiency upgrades for potentially no up-front cost

ALL New Jersey utilities currently have programs that offer incentives that cover up to 70% of the up-front cost of an energy efficiency upgrade. NRM can help take advantage of those incentives with high-impact improvements for your commercial refrigeration system.

List of utilities NRM works with

What kind of improvements will I see?

NRM’s unique and proven smart controls improve the operation of your refrigeration system from top to bottom. Beside adapting your system’s cooling schedule from running continuously to need-based, the controls also improve your ability to track temperatures, defrost your evaporator fans, address temperature issues, and more.

Have you ever stopped and considered why your refrigeration needs to run just as hard in the middle of January as it does in the middle of July? The short answer is it actually doesn’t need to. NRM’s efficiency measures can reduce your system’s runtime by an average of 40-60% without jeopardizing food safety.

One of the main contributing factors to the inefficient operation of a commercial refrigeration system is old, outdated equipment components. Most systems we encounter are 10-15+ years old, which means much of the hardware can be upgraded to higher efficiency versions.

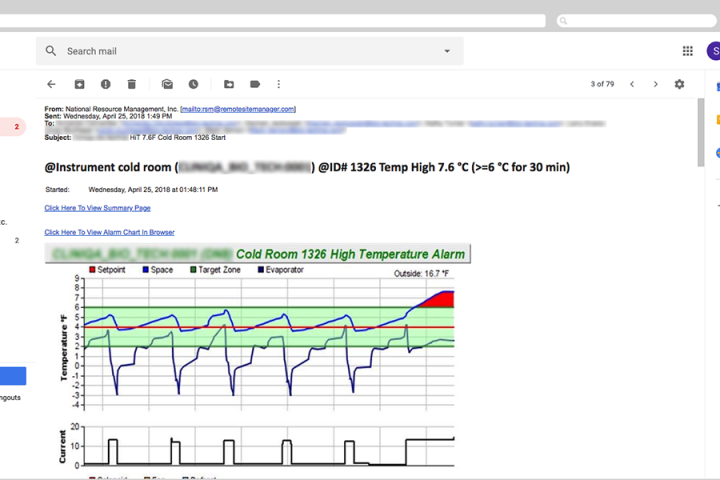

Another leading cause of inefficient, wasteful operation of your refrigeration system is the existence of unseen mechanical issues. Not only do these kinds of issues sap your system of effective cooling, they could lead to a catastrophic failure that risks your perishable cold product. NRM’s controls will alert you immediately if they detect an issue.

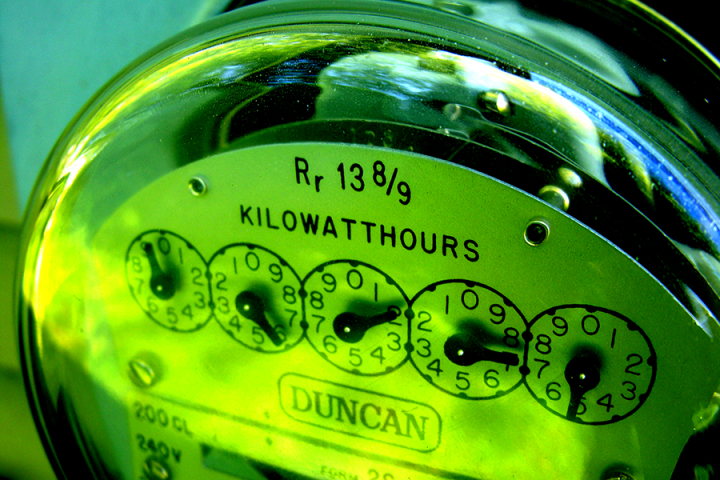

Along with better operation and oversight, NRM’s solution delivers proven, verifiable energy savings that will lower your monthly commercial electric bill. Because the savings can be tracked and verified, BGE trusts NRM’s results enough that they’re the exclusive vendor for refrigeration controls and measures.

The quickest way to secure your assessment is to have us call you to schedule it:

The program’s no-cost assessment is a quick but crucial first step in getting your project underway, and also qualifying for utility-funded incentives.

The assessment consists of an NRM Energy Advisor analyzing your refrigeration’s current operation in a walk-through that usually takes 15-20 minutes to conduct. They note what kind of equipment your system has, runtimes, where parts are located, and a sketch of the walk-in cooler’s or freezer’s layout.

CoolTrol® is the backbone of every turnkey solution for the Direct Install programs.

It's more than a "new" thermostat. CoolTrol gives you full control over the operation of your refrigeration system — from bypass features to one-button defrost cycles to temperature settings on the fly to safe temperature range alarms and more — while also providing long-term "set it and forget" energy savings. Every feature was designed with the end user in mind.

It couldn't be easier to get.

STEP 1.

System Assessment

An NRM specialist conducts a thorough assessment of your refrigerated space, noting everything from current runtimes, total number of compressors and evaporator fan sets, hardware components used, and more. These findings, along with a copy of your commercial electric bill and a sketch of your cold space, are then sent off to NRM engineers to generate your analysis.

STEP 2.

Energy Analysis

Next, NRM engineers analyze the data from the assessment. They calculate how many kilowatt hours can likely be reduced from your energy consumption through both reducing runtimes and adding high-efficiency hardware, and in turn, how much money you could potentially save on your electric bill. All calculations can be measured and verified by observing new runtimes.

STEP 3.

Incentives Application

Following the analysis, NRM applies for the any eligible utility incentives on your behalf. In some cases the utility may offer funds only for certain measures, and in other cases, they offer incentives for the entire refrigeration solution. In addition, some programs offer on-bill financing for zero out-of-pocket cost. NRM works to secure every dollar available for your project.

STEP 4.

Project Proposal

Once all the info is compiled, NRM presents the project scope to you, and any necessary partners, for your approval. It includes measures to be implemented, and long-term energy savings projections. NRM is also happy to explain the project to any additional staff who will be impacted—such as your refrigeration technician, store manager, or Facilities Director.

STEP 5.

Project Approval

After reviewing the proposal, the next step is approving both the measures and cost of project. Once approved, NRM works with you to schedule the installation at a time most convenient for you. NRM’s measures and upgrades are typically implemented with zero disruption to your normal business hours, and is completed by licensed professionals.

STEP 6.

Retrofit Installation

When the installation is complete, NRM provides training for its controls as well as offering 24/7 tech support. But most importantly, all that’s left to do is enjoy the long-term benefits of your new refrigeration management system. Set-it-and-forget-it smart controls deliver energy savings, and the hardware upgrades extend the life of your equipment through less wear and tear.

"This was a win-win for us. We decreased our monthly utility costs while simultaneously improving the shopping experience for our customers by having more comfortable aisle temperatures and better product displays."

— John Doyle, Owner

Call an NRM Energy Advisor directly to get your asssessment: 732-606-5459 (Nora)

Mid-Atlantic Success Stories

MD Food Bank

Salerno's Seafood

Shop N' Bag Chain

Domino's Pizza Chain

"NRM has been outstanding through this whole program. Your technicians were very professional, and during the last project, even took the time to answer questions from my refrigeration guy so he could properly interact with the controls moving forward. And the energy savings help everyone’s bottom line. If the utility companies can’t find new ways to generate electricity, our costs are going to go up substantially, so this is a way we all can help."

— Bruce Reamer, Owner