California Schools,

Rethink your Refrigeration

Address potential cooling issues more proactively, while simultaneously improving the operation and efficiency of your refrigeration system

What kind of info are you looking for today?

It's easy to rethink both how you deal with food safety issues and how you manage operations

NRM’s refrigeration upgrades have been honed over the years to be a complete solution that provides multiple benefits to multiple stakeholders.

Whether helping the kitchen manager and their staff with their daily duties, offering alternative savings measures to the sustainability officer, or ensuring temperatures are always at their proper, safe points for the students who rely on you to keep their food safe.

For example, imagine receiving a notification on a Saturday afternoon to a refrigeration emergency and being able to dispatch a technician out to your school immediately instead of walking into a warm cooler Monday morning.

Everyone stands to gain something.

Most common areas we find performance upgrade opportunities:

Smart Controls

NRM’s unique refrigeration controls offer a full spread of enhancements to your commercial refrigeration system. From tracking insightful operational data to optimizing multiple components of the system, your system can achieve so much more than just “running all the time.” You’ll have actionable data and one-touch settings at your fingerprints at all times.

Evaporator Fan Motors

Optimizing your evaporator fans is one of the simplest but most effective ways to see big efficiency improvements in your operation.

Most fan sets run 24/7 whether they need to be running to satisfy temperatures or not. Think about it: your evaporator fans are running while you sleep even though no one is using the cooler, costing you more money on your electric bill.

NRM can control the fans to run only when they’re required to satisfy space temperatures. This typically reduces their runtimes by 40-60%.

Anti-Sweat Door Heaters

The anti-condensation door heaters on your product coolers are typically a large opportunity for energy savings. By default, these heaters are on all the time, regardless of whether there are customers opening and closing the doors constantly creating moisture.

NRM’s controls can reduce their runtimes by 85-95% and only run when they have to.

Novelty Cooler Runtimes

Does it seem wasteful for your small product coolers storing water and soft drinks to keep running even when your business is closed? Especially when you consider that things like soda are unaffected by changes in temperature.

These stand-alone coolers can be optimized to run around your business hours.

Evaporator Coil Defrost

Standard defrost intervals can be okay in many cases, but they often don’t occur when you actually need them, and you’re left calling a technician to come out an expensive service call to de-ice the coils in your walk-in.

With NRM’s solution, you’ll gain the ability to start a defrost whenever you notice ice buildup with the push of a button. Or even from your phone!

Call, Text or Email our CA Advisor, Joe Isaacs, at 916.629.4436 or jisaacs@nrminc.com

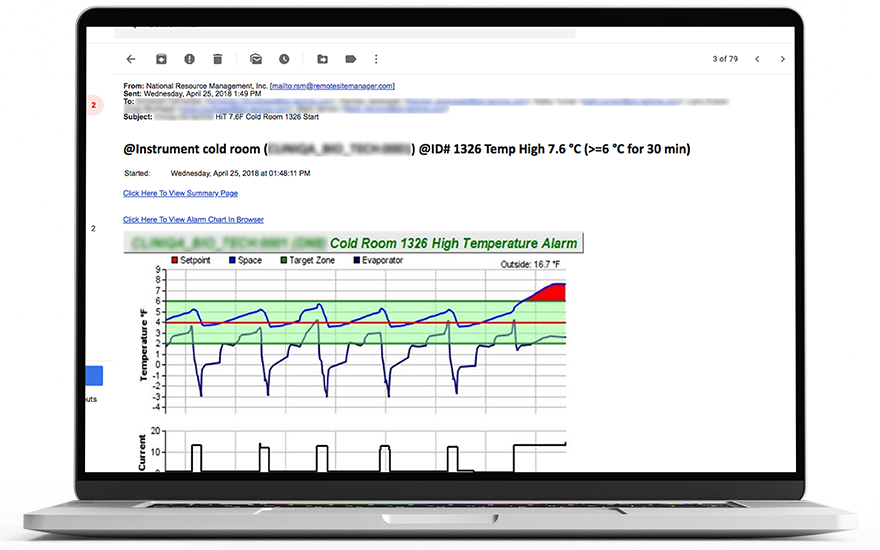

Avoid food safety crises with a wealth of operational data and proactive insights

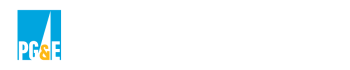

Whether you have 1 cold space in a single school kitchen, or 100 cold spaces spread across an entire district, our live summary page gives you an immediate overview of all your cooling activity.

Quickly consult current and 7-day runtimes, cooling status, temperature settings, and address any alarms that have been triggered.

Consider the amount of time and effort you’d save by having critical operational info all conveniently in one place.

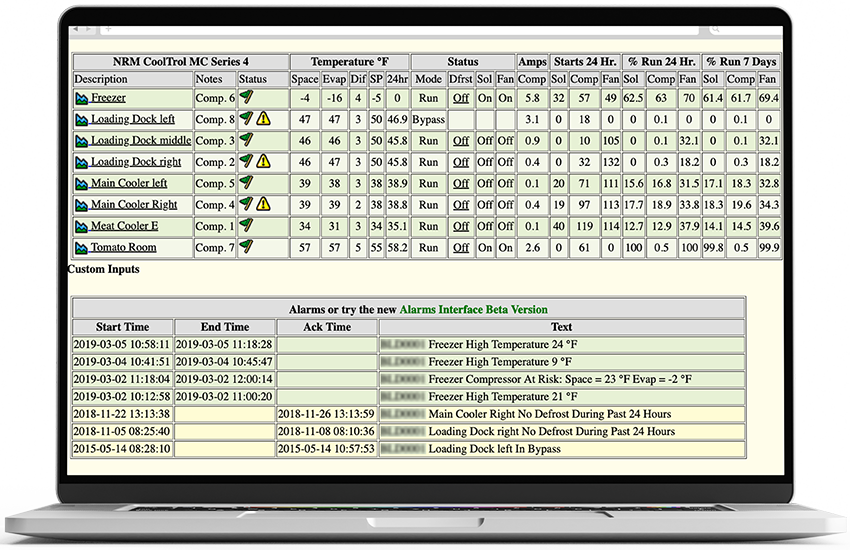

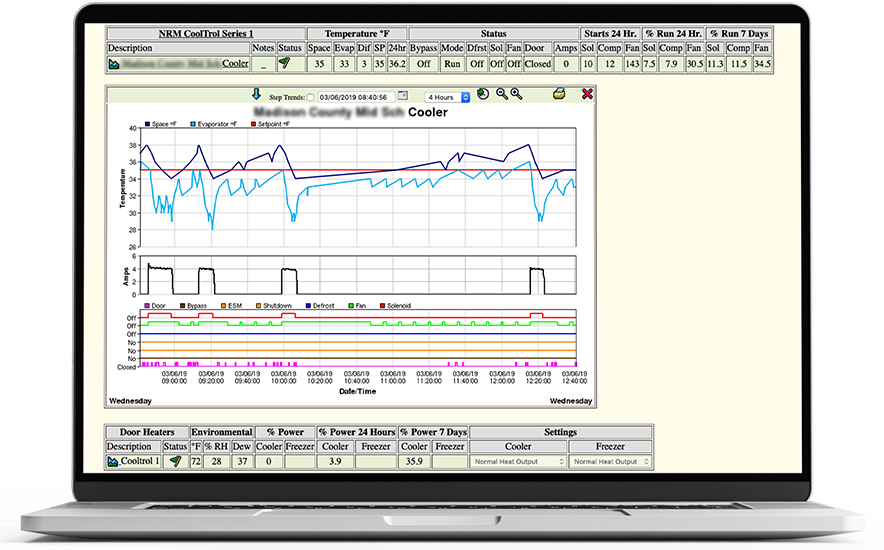

Arm yourself with powerful and unique visual diagnostics graphs to pinpoint exactly when and where an operating issue arises. Troubleshooting becomes more efficient and effective, helping to ensure the issue is resolved on the first technician visit.

The graphs show important but often overlooked components such as amperages, compressor cycles, the solenoid valve, and things like whether a door is open or not.

The monitoring platform offers transparent runtime and temperature data that provide the measurement and verification proof for accurate recordkeeping.

These graphs also allow you to actually see how much less energy your refrigeration system is using. While also tracking that safe temperatures are always met.

Store up to 10 years of operational logs that take the human-error component out of tracking temperatures.

Going beyond a high temperature alert — which occurs only after an issue has already disrupted operations — NRM’s platform provides a suite of early detection notifications to help you be more proactive with troubleshooting.

For example, a compressor that’s short cycling will still likely be able to cool the space, but it’s dangerous, unnoticed overuse could lead to a critical system failure, jeopardizing the entire cooler’s worth of food.

"In our Annenberg dining hall freezer, our compressors were on the verge of burning out, and we would never have picked up on it if not for the monitoring software. Not only did the alert save the compressor, which is a multi-thousand-dollar repair in itself, but potentially a freezer’s worth of product that might have been lost otherwise. The online interface is also very slick -- I love it."

— Bob Leandro, Director of Facilities

Free downloadable resources for the kitchen

DAILY/MONTHLY TEMPERATURE LOG

YEARLY MAINTENANCE CALENDAR

SAFE COLD STORAGE TIMES CHART

Relevant links from around the web

[ARTICLE]

Most common questions we get asked

How can NRM's solution save so much energy?

Refrigeration and HVAC equipment are sized for THE HOTTEST DAYS of the year, and they always add a safety factor in case more is needed. But the “hottest days” only happen 20-30 times per year, which means all systems are oversized for the other 330~ days. The CoolTrol® system manages all the loads to take advantage of the oversizing, and turns off loads that don’t need to be on all the time. It also manages defrost more closely to what is needed. Some facilities have very big cold rooms so they add redundant systems meaning that capacity can sometimes be 2-4x of what is needed on average days.

My refrigeration tech says it's not safe to turn off my evaporator fans. Is that true?

In an unsafe manner, yes. But with NRM’s solution, it is perfectly safe. Implemented in over 50,000 systems to-date, the new controls keep fans running when refrigeration is ON and only cycles them OFF and whenever refrigeration is OFF. Every running fan motor generates heat and the new system run time when air movement is not necessary. Why keep the heaters running once temperature set point is reached?

What kind of guarantee can you provide me that these savings are real?

NRM has earned the utility’s trust and confidence, which is the greatest guarantee we can offer. In some programs, NRM has been providing solutions since 1997 with the local utility company’s backing. We would not continue to win these contracts year over year if we didn’t produce deliver the projected savings.

Why is the utility company paying me money to use LESS energy?

Most states have adopted laws to get citizens and companies to use less energy as it is more economical to encourage consumers to use less energy through incentives than to build a new power plant which no one wants near them. Utilities are tasked with collecting a fee on your utility bill based on usage. It may be a line item shown as “public benefit charge” or “energy conservation charge”. This money accumulates and is used to fund the incentives that pay for energy efficiency optimizations.

Since it is available for all ratepayers, it is a great way to fund energy efficiency programs that give capacity back to the electrical grid while also reducing your commercial electric bill. So, it’s a smart investment to participate in the programs and to take advantage of the incentives to get some of your money back through upgrades to your own equipment.

The money isn’t free, but it will contribute toward qualified energy efficiency projects. It’s a great way to make a difference to your bottom line.

How much incentive do I qualify for?

It really depends on how much energy a project can save… just think of it as the utility buying capacity from you to prevent overtaxing the energy grid. The power you save now becomes available to new customers. To find out what you can get, we recommend a no cost assessment of your current system that will enable us to calculate savings that we then present to your utility company who allots the amount they will pay for your capacity. If your systems already are considered partially or totally energy efficient, there may be little or no opportunity for reducing energy or qualifying for an incentive.

What level of technical proficiency is required to use CoolTrol®?

CoolTrol® is designed specifically for you, the end user. It is equipped with software developed by NRM and is designed to intelligently operate equipment at optimum energy efficiency. It becomes your new refrigeration thermostat that takes advantage of every opportunity for saving energy. It has many user-friendly features and a superior user interface compared to traditional refrigeration thermostats that are primarily designed for technicians, not end users.