Everything from office buildings to restaurants to convenience and grocery stores use large amounts of energy for lighting, space cooling and heating, or refrigeration. And in almost every case, these commercial systems can have their energy consumption reduced by up to 30% resulting in lower utility costs, optimized equipment operation for improved efficiency, and a gained competitive advantage for the business.

Who couldn’t benefit from more profits as a result of spending less on overhead associated with energy? Here are 5 tips to get you thinking about your utility expenses and begin strategizing to get them lowered:

Routinely check the HVAC economizer.

Many office buildings, convenience stores, and restaurants have economizers on their air conditioning equipment. This is a controlled vent damper that draws cool outside air into the system (when it’s available) to reduce the need for mechanically cooling circulated air. But if it’s not checked periodically, the linkage on the damper can seize up or break. If either of these occurs, the economizer could remain open and become very costly on your utility bill.

“An economizer stuck in the fully open position can add as much as 50 percent to a building’s annual energy bill by allowing hot air in during the air-conditioning season and cold air in during the heating season. Have a licensed technician check, clean, and lubricate your economizer about once a year, and repair it if necessary.1”

Consider scheduling load-intensive operations.

While this applies mainly to reducing the costs associated with peak demand, staggering your load-intensive operations or scheduling them only when your facility’s demand is low, can have very positive effects on your utility expenses. This can be achieved through smart controls, like refrigeration control systems or lighting sensors, to limit the impact of all-at-once energy consumption. Cardboard box compactors can be scheduled for off-peak use, as an effective office-building method.

“Demand is a measure of the rate at which energy is consumed. The demand an electric company must supply varies with the time of day, day of the week, and the time of year. Peak demand seldom occurs for more than a few hours or fractions of hours each month or year, but electric companies must maintain sufficient generating and transmission capacity to supply the peak demand. Demand charges represent the high costs that electric companies pay for generating and transmission capacity that sits idle most of the time.4”

It begins with identifying the time of day that your facility uses its most energy, then cycling loads when employee or consumer comfort levels won’t be affected. For lighting, it could be using sensors that turn off lights when there are no occupants in a room or on a floor. For refrigeration, it could be through controls that turn off the system when certain temperatures are met or during non-business hours. For HVAC, it could be sensors that control ventilation based on occupancy, or initiate temperature setbacks when certain conditions are met, or even completely shutting off a portion of the system.

Retrofit refrigeration and lighting with energy-efficient options.

In the commercial space, if a business utilizes refrigeration systems (restaurants, c-stores, grocery stores, liquor stores), these systems typically account for 40 to 60 percent of the energy consumption. They’re such energy hogs because refrigeration is typically running 24/7 and it’s set up to run exactly the same as when it was first installed—which was 10 to 30 years ago in many cases.

By replacing traditional shaded pole motors with electronically commutated motors, installing night covers or glass doors on display cases, and using controls that optimize the energy usage of a walk-in or reach-in, a commercial business can see a substantial amount of energy reduction—as much as 50 percent in some cases. When reducing motor or lighting loads in coolers and freezers, you get another 20-40% savings on refrigeration as heat from those loads are reduced.

The same can be said for lighting. Retrofitting commercial lighting with LEDs can show serious gains.

“LEDs can be used for both indoor and outdoor applications. LEDs last up to 50 times longer than incandescent bulbs, use much less energy to operate, provide more consistent white light and are readily adaptable to dimmers and other commercial lighting controls. LEDs are especially good for refrigerated cases, since they perform much more effectively in cold temperatures than other types of bulbs.2”

Re-Commissioning and preventative maintenance.

Whether the business needs are commercial or industrial, whether there’s lighting, HVAC, and refrigeration or just one of the three, one of the most oft-overlooked areas for reducing energy is in simple preventative maintenance.

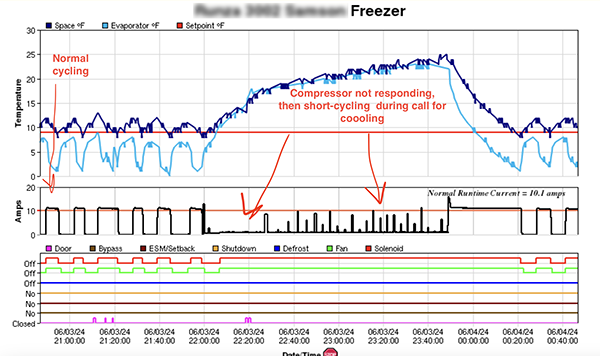

By routinely having your energy-using systems checked by certified technicians, you can get the jump on potential problems that could wind up being catastrophic and far more costly than the price of a maintenance visit.

Dirty or damaged components can increase the amount of energy needed for the system to achieve even its most basic functions. Filters, coils, fan belts, and fans for a refrigeration or HVAC system require check-ups the same way tires, belts, and hoses do for a car.

“Commissioning is a process in which engineers check and tune up building systems to ensure that they are operating appropriately and efficiently. Studies have shown that continuously monitoring a building’s energy systems can lead to reductions of 10 to 15 percent in annual energy bills. For the typical 50,000-square-foot office building, that’s equal to about $11,000 in savings per year!1”

If one were to then implement the process of monitoring-based commissioning or Continuous Commissioning, even greater savings can be achieved. Continuous Commissioning, as defined by the Energy Systems Laboratory at Texas A&M, is an ongoing process to resolve operating problems, improve comfort, and optimize energy use for existing commercial and institutional buildings and central plant facilities. Continuous Commissioning incorporates and extends existing building commissioning practices.

“Applying the Continuous Commissioning process adds an additional 15% to 45% savings over a normally commissioned building as measured by the methods outlined in the USDOE’s International Performance Measurement and Verification Protocol (IPMVP1), which is the current revision of the North American Energy Measurement and Verification Protocol (NEMVP). The CC techniques developed at the Energy Systems Laboratory involve monitoring and solid engineering analysis of mechanical systems and occupant needs. Increased skills and training are needed to obtain energy savings in buildings today. CC addresses this need.5”

Scrutinize and keep a log of your monthly utility bills.

This may be the so-obvious-its-never-thought-of solution on this list. While implementing energy efficient equipment or making sure the equipment you currently have is running at its most optimal can show impactful reductions, reducing energy consumption really begins at inspecting the charges on your utility bill and then developing a strategy and plan to lower them.

Where are the energy-demand spikes in your business? When and how often do they occur?

“With electricity consumption on the rise and utilities struggling to keep pace with market and regulatory changes, demand charges can account for a significant portion of business users’ utility bills – at times between 25-50 percent. Furthermore, in contrast to rates outside of peak periods, demand charges have been rising steadily, year after year.3”

Understanding the different types of energy usage and how you’re being charged for them is critical to wrangling utility expenses.

“If you were billed just for consumption, you would have no monetary incentive to reduce your peak demand. Because you are charged for demand, it is extremely helpful to know the monthly peak demands for a typical year, your demand profile for the day your peak demand occurred each month, and if possible, the daily peak demands for the entire year. The daily demand profile is a plot of your electrical demand for each hour of the day. This information is helpful in determining when, how long, how much, and how many times each month you will have to employ a strategy to reduce peak usage.4”

The goals of this blog post were to get you thinking about your energy charges, what types of factors contribute to those expenses, and to introduce a few tips to begin grappling with your energy consumption. Most systems today stand to benefit from some form of improvement or optimization, and whether through professional, technical solutions or do-it-yourself methods, it all starts with information and awareness.