Here, we’ll unpack some of the ways you can make sure that your energy-efficiency retrofit doesn’t turn into a refrigeration headache!

Look for a strong reputation.

There is no substitute for proven real-world results. This applies to both the technology and the implementer. Make sure that the controls hardware and the implementation installer both have experience in businesses like yours. The best controls and implementers have many years of lessons learned, in thousands of coolers and freezers.

Service and support.

The process doesn’t stop at installation. Refrigeration doesn’t sleep, and it doesn’t take weekends off. Can you get expert help on a Friday night, if there is a question about the system’s performance?

A meaningful warranty.

Electronic controls are usually very reliable, once they are set up correctly. But what if there is a problem, question, or concern? When your refrigeration technician has questions about system operation, can they call and talk to someone knowledgeable, or will they be stuck talking to a sales rep?

Proven results.

The quickest way to find proof of real-world results is to ask about third-party M+V (measurement and verification) studies. An M+V study is when independent engineers go out to an installed system and measure and verify the achieved historical energy savings. The best implementers and technologies will have years’ worth of this type of data, and will be happy to share it with you.

Serviceability.

If you own a cooler long enough, sooner or later you’re going to have an unfamiliar technician servicing it. When the “new guy” is up on the roof trying to diagnose a mechanical issue, is he going to understand the energy management controls? Does it have an easy bypass, or will he need to wire it out of the system in order to service your equipment? The best controls come with a transparent wiring scheme, complete documentation, excellent technical support, and most of all, a fail-safe bypass.

UL Listing for refrigeration controls.

UL is best known for their safety testing. But with HVAC/R controls, they actually go a step further and test for reliability as a safety issue. To be UL listed for refrigeration controls, a switching system needs to be tested for at least 30,000 cycles, which is far more rigorous than the generic standard.

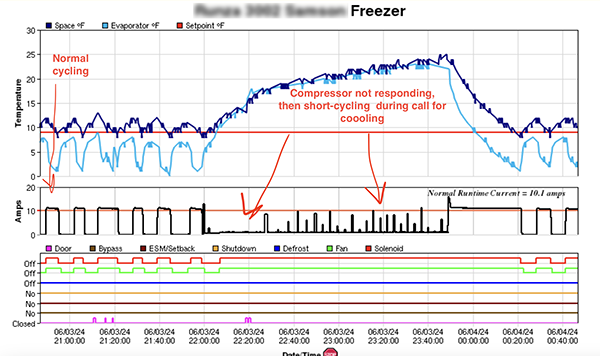

We have been focusing on some of the risks and challenges, and with good reason. But the upside to a well-implemented controls retrofit can be huge. The most advanced controls on the market bring a whole suite of features and capabilities, including adaptive defrost control, web connectivity, intelligent alarms to alert you (or your refrigeration contractor) of a problem before you have a temperature out of range, sophisticated diagnostics and data analytics, and powerful controls for your entire refrigeration system.

The energy savings from fan controls often comprise the most obvious financial justification, but improved controls can actually deliver a comprehensive Management System for your whole cooler or freezer, with a host of operational, loss-prevention, and maintenance benefits.