In nearly every state, energy efficiency programs exist to help business owners, residents, government institutions, schools—and most other entities that utilize energy—conserve said energy and prevent waste. Through these programs, retrofitting of equipment loads such as refrigeration, lighting, and HVAC, is incentivized either monetarily or by other mechanisms that ease the cost of an energy saving project.

The goals and parameters for these efficiency programs, administered by the state’s utility companies or third-party contractors, are set by the state’s Public Utility Commission in conjunction with data and research. Among the various parameters set for a program, one of the most critical is the means by which energy savings are determined and reported for technologies falling within the program. Some states adopt a deemed savings approach for their calculations and others utilize a calculated savings approach. As a company that has been retrofitting energy systems for twenty years, we’ve had experience with both and this post was written to express why we believe using a calculated approach is best in any customer-facing role as it relates to these programs.

NOTE: Many times, these calculation methodologies can be found in your state’s Technical Reference Manual.

There is a simple but clear difference between the two approaches. In a deemed savings approach, pre-determined kW and kWh savings are attributable to energy efficiency measures in a particular type of application and in a calculated approach, specific variables involved in the application must be determined beforehand to then calculate the savings.

Here’s a quick example to illustrate the difference: say we were to retrofit a T-12 to an LED. In a deemed approach, the kW and kWh savings are pre-determined based on the application of the new technology (the T-12) sometimes regardless of the specific wattage or run hours of the LED. In a calculated approach, you would take the difference in the wattage between the existing and new technologies, and factor in the run hours of the lighting, to determine the savings.

The deemed savings approach is preferred by most states, as it levels the playing field amongst program implementers by using averages across a technology’s application portfolio. This makes it easier and quicker for utilities and contractors to report savings, and helps eliminate errors by not using actual nameplate data in projections. But as alluded to earlier, and drawn from our daily interactions with utilities and customers, we believe the calculated approach should be used any time savings are discussed or presented with customers.

Why? Let’s use another real-life example.

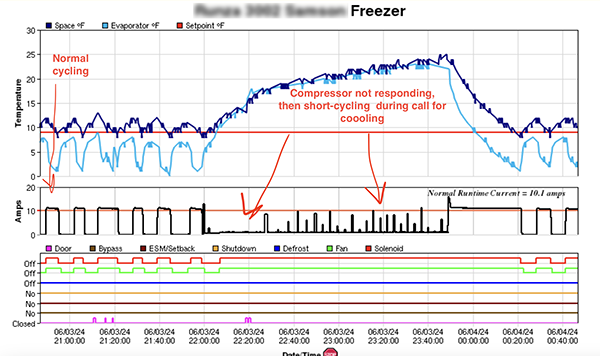

In one state, we audited a site to install an anti-sweat heater control system on a 10-door walk-in cooler. Based on the actual kW load of the door heaters found in the data on the cooler’s nameplate, we calculated the energy savings would be 5,619 kWh. For this particular state, if we used a deemed approach, the same set of doors would be determined to have 12,980 kWh in energy savings because that’s the average applied to 10-door systems under the state’s guidelines.

This deemed savings number was actually greater than the energy usage of the doors prior to retrofitting!

Not to mention, that’s quite a large difference between the savings projections. Hopefully, it’s obvious as to why the calculated is preferred when dealing with customers. If deemed savings are “quoted” on a project, and it happens to differ greatly from the calculated/”real” savings, the potential negative effects could just snowball past a point of no return.

Good news travels fast. Bad news travels at warp speed. If customers feel they have been overestimated on their energy savings, they will not talk positively about the energy efficiency program to other business owners. The reputation of the program, the reputation of the contracting company, and the perception of energy efficiency as being a good thing, could all take huge hits. Ultimately, this could hinder a state’s ability to meet their energy goals and that’s no good for anyone!

There is no “right” approach. They both serve a purpose and both are utilized. The biggest thing to keep in mind is whom are you interfacing with about the energy efficiency program? That should determine which approach you use.