Last week, we wrote about why you need electric defrost for your commercial freezer and how it works. Here’s a quick refresher. A defrost system is necessary in walk in freezers that maintain product temperature at or below freezing to prevent build-up of ice around the evaporator. This helps avoid equipment failure and maintain highest operating efficiency.

At certain times of the day (usually 4 times a day), a time clock is programmed to turn off the refrigeration and evaporator fans, and turn on the electric heater elements in the coil. This cycle is usually programmed to run up to 30-45 minutes and as the heater elements heat up to a preset termination temperature of 100-120 degrees Fahrenheit it then drops out of defrost mode. During this cycle, any built up ice will melt and drain away so when refrigeration turns back on the evaporator coil is clear of ice. The more ice there is on the coil, the longer the defrost duration.

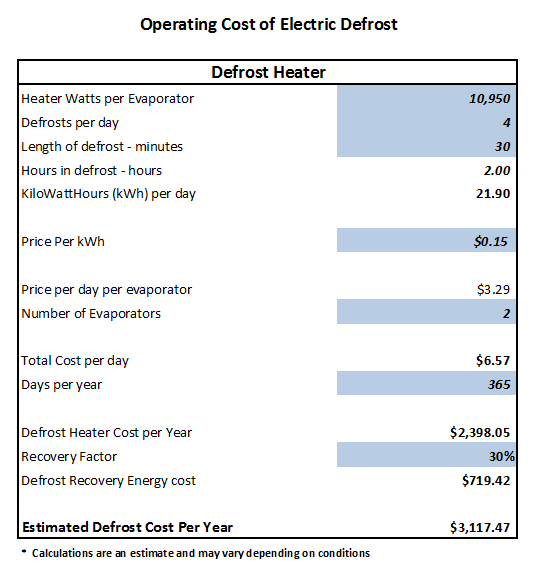

How much does it cost to defrost a commercial freezer?

Heater element calculation: (kilowatt-hour = watts × hours on / 1000).

A defrost heater rating of a typical medium sized commercial freezer evaporator coil producing 46,000 BTU/h of cooling is 10,950 watts. As mentioned above, an average defrost cycle lasts about 30 minutes and occurs 4 times a day resulting in two hours of run time. Utility companies charge based upon $/kWh usage and charge separately for the peak kW achieved during the month. Utility rates vary, but let’s use an average $0.15/kWh for our calculations.

(10,950W x 2h) / 1000 = 21.9kWh

21.2kWh x $0.15/kWh = $3.29 per day, per evaporator

Defrosting 2 evaporators = $6.72 per day

In order to defrost, some heat is introduced into the space that is keeping product frozen to melt ice buildup. The coil needs to be cooled down quickly by the refrigeration system before regular cooling can resume.

The evaporator fans are off during defrost and remain off while the refrigeration system starts to quickly cool the coil to below freezing at which point the evaporator fans can resume operation. This cooling and removing of any heat that was introduced into the space is called the recovery period. The energy needed for recovery is usually around 30% what the defrost heaters used to defrost the coil.

To get a more accurate cost of defrost, we also have to measure and calculate the energy cost of recovery. We do this by determining: 1) amount of power (aka watts) the evaporator fans and the compressor draw, and 2) how long the system needs to run in order to remove the BTUs that were introduced into the space from the electric defrost cycle. Once determined, the sum of these two calculations can be added to the cost of energy to defrost in order to determine the annual cost of electric defrost.

In our example below, we use the 30% recovery factor that equipment manufacturers and engineers have determined to be a fair value. As you can see below, it costs a lot of money to run electric defrost!

Download the calculator tool shown above to estimate the cost of electric your defrost.

Check back next week for the conclusion to this series of blog posts where we will discuss how to spend less on your utility bill by making electric defrost more efficient.